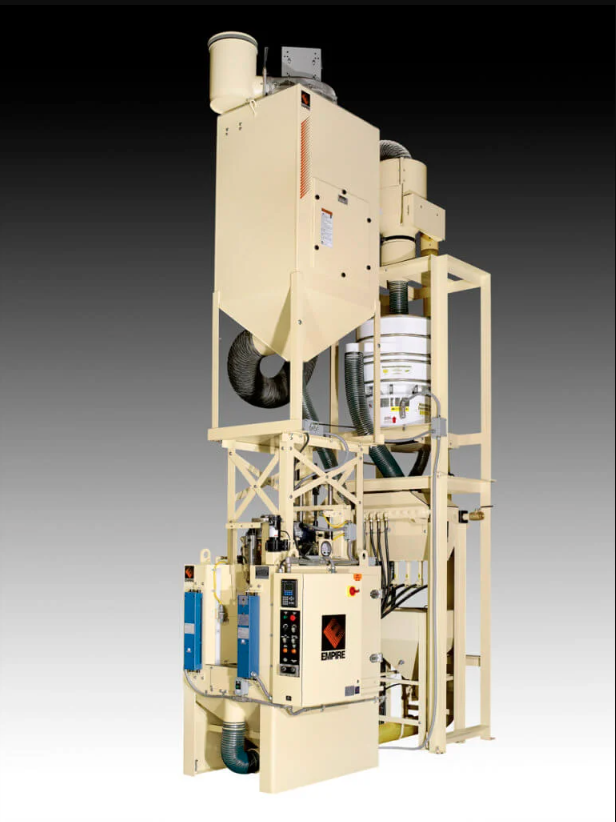

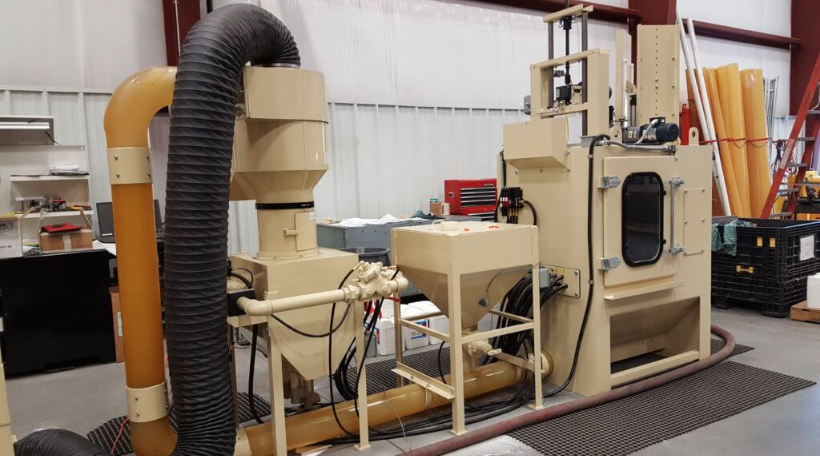

Indexing Turntable Machines

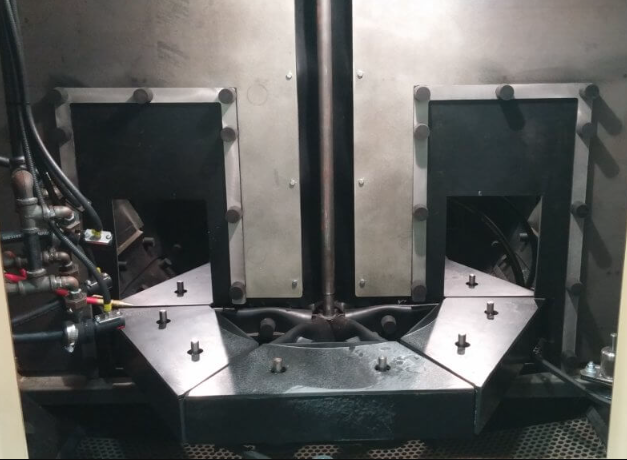

Indexing Turntable systems provides precise positioning of the workpiece in front of blasting nozzles for guaranteed repeatability of process requirements. These units allow for a variety of loading and unloading options, ranging from simple manual operations to more sophisticated robotic operations.

Buffalo Manufacturing offers a variety of standard Empire platforms along with custom systems to accommodate almost any size work piece. Depending on customers’ production requirements, configurations can range from 2 -24 rotating part stations. Along with precise positioning of the indexing turntable, the rotating part stations add to the assurance of quality and complete part coverage during the blasting cycle.

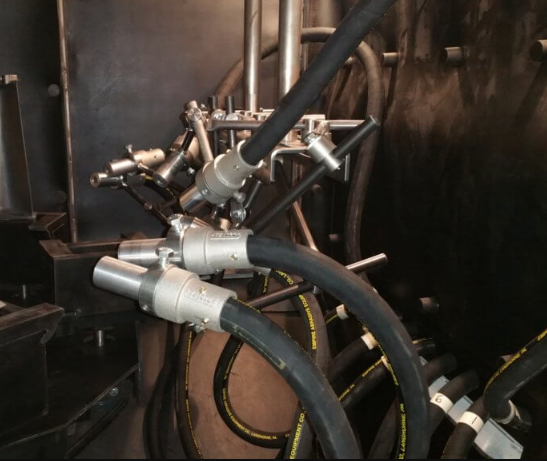

These systems also allow for various nozzle manipulation packages ranging from simple stationary nozzles, and horizontal/vertical linear operations to more sophisticated robotic movement.

Conventional Indexing Turntable Systems

(click image to enhance)