Mass Finishing

Equipment

Industrial Cleaning and Finishing Experts

Buffalo Manufacturing is one of the country’s largest distributors of high-quality mass finishing equipment, offering Hammond-Roto Finish mass finishing equipment, dryers, and sound covers:

Hammond-Roto Finish Co. specializes in engineering and manufacturing mass finishing systems, ranging from simple single-machine units to fully integrated multi-machine systems.

HR Series

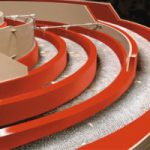

The workhorse of the Spiratron® family of vibratory finishing machines, the HR Series has evolved since its original patent notoriety of being the first round bowl internal separation machine. The HR is a heavy duty machine that can be customized with a wide variety of standard and special options that gives the customer a full range of processing possibilities – from minimal human involvement to a fully automatic system for a hands off operation.

Features

- Heavy Duty Welded Steel Construction

- Main building component of the bowl is a certified pressure vessel tank head.

- Cast Polyurethane Liner

- Polyurethane liner is cast, not sprayed on. This improves media rebound and provides more wear depth.

- 50% additional lining in high wear areas.

- “U” Shaped Straight or Curved Wall Processing Bowl

- Full 90º Wrap-Around Separation Screen

- Premium Efficiency, Ball Bearing, Cast Iron Motor

- TEFC, 1800 RPM, 230/460V

- Water-Driven Compound System

HR Combo

The HR Combo Series features the same structural design as the HR Series machines, but also adds a second chamber for parts drying. This structure utilizes the same tank head design for structural integrity. The addition of the second chamber to the outside of the process area reduces costs and floor space. With unload gates available for both the processing and drying channel, this is one of our most versatile machines.

Highlights

- One Drive System

- One Machine that Processes & Dries Parts

- One Electrical Panel

- Smaller Footprint

Features

- Heavy Duty Welded Steel Construction

- Main building component of the bowl is 1/2” thick pressure vessel material.

- Cast Polyurethane Liner

- Polyurethane liner is cast, not sprayed on. This improves media rebound and provides more wear depth. 50% additional lining in high wear areas.

- “U” Shaped Straight or Curved Wall Processing Bowl

- Full 90º Wrap-Around Separation Screen

- Premium Efficiency

- T-frame Motor 230 or 460/3/60 Specify 230 or 460 volts. Motor is mounted to non-vibrating base. Belt drive to main shaft for 1,250 V.P.M.

- Water-Driven Compound System

- Heat Lamp(s), with Control Panel Mounted Controls

HR Long Radius

The Hammond Roto-Finish HR Long Radius Series of Vibratory Machines are designed for a very high range of performance. The Long Radius has many advantages over the standard HR Machines:

Highlights

- Higher Amplitude

- More Uniform Part Processing

- Better Feed for Longer Parts

- Capable of Continuous or Batch Processing

Features

- Heavy Duty Welded Steel Construction

- Main building component of the bowl is 1/2” thick pressure vessel material.

- Cast Polyurethane Liner

- Polyurethane liner is cast, not sprayed on. This improves media rebound and provides more wear depth. 50% additional lining in high wear areas.

- “U” Shaped Straight or Curved Wall Processing Bowl

- Full 90º Wrap-Around Separation Screen

- Premium Efficiency

- T-frame Motor 230 or 460/3/60 Specify 230 or 460 volts. Motor is mounted to non-vibrating base. Belt drive to main shaft for 1,250 V.P.M.

- Recirculating Oil Lubrication System

- Oil return flow is monitored so even line breaks will be detected. Mounted in machine base. Available externally for ease of service.

- Water-Driven Compound System

HR Long Radius Combo

The HR Long Radius Combo Series features the same structural design as the HR Long Radius Series machines, but also adds a second chamber for parts drying. This structure utilizes the same tank head design for structural integrity. The addition of the second chamber to the outside of the process area reduces costs and floor space. With unload gates available for both the processing and drying channel this is one of our most versatile machines.

Highlights

- One Drive System

- One Machine that Processes & Dries Parts

- One Electrical Panel

- Better Feed for Longer Parts

- Smaller Foor Print

Features

- Heavy Duty Welded Steel Construction

- Main building component of the bowl is 1/2” thick pressure vessel material.

- Cast Polyurethane Liner

- Polyurethane liner is cast, not sprayed on. This improves media rebound and provides more wear depth. 50% additional lining in high wear areas.

- “U” Shaped Straight or Curved Wall Processing Bowl

- Full 90º Wrap-Around Separation Screen

- Premium Efficiency

- T-frame Motor 230 or 460/3/60 Specify 230 or 460 volts. Motor is mounted to non-vibrating base. Belt drive to main shaft for 1,250 V.P.M.

- Recirculating Oil Lubrication System

- Oil return flow is monitored so even line breaks will be detected. Mounted in machine base. Available externally for ease of service.

- Water-Driven Compound System

- Heat Lamp(s), with Control Panel Mounted Controls

HR Spiratron® Flat Bottom

The HR Spiratron® Flat Bottom machines are ideal for large component finishing. Used for batch processing, the machine is loaded and unloaded by piece by hand. For small parts and part on part, it is unloaded through the unload plug or door. NOTE: Some applications are possible with a magnetic belt separator.

Features

- Heavy Duty Welded Steel Construction

- Main building component of the bowl is 1/2” thick pressure vessel material.

- Cast Polyurethane Liner

- Polyurethane liner is cast, not sprayed on. This improves media rebound and provides more wear depth. 50% additional lining in high wear areas.

- “U” Shaped Straight or Curved Wall Processing Bowl

- Mounted to Non-Vibrating Base

- Cartridge Drive System

- Features adjustable top and bottom eccentric weights. Drive exchange program with in-stock availability.

- Premium Efficiency, Ball Bearing, Cast Iron Motor TEFC, 1800 RPM, 230/460V

- Water-Driven Compound System

Multi-Pass®

Hammond Roto-Finish Multi-Pass® machines are unique in the mass finishing industry. A Multi-Pass® machine can operate in a continuous operation or it may be used as a batch process machine. What makes the finishing power so unique? A part is surrounded by a finishing media with space between itself and other parts. On a continuous basis a new part is introduced to the Multi-Pass® machine within an interval such as from a grinder. This part then moves through the channel maintaining that same interval from the next part introduced. This first in – first out sequencing ensures lot integrity.

The Multi-Pass® machine also features internal separation, which keeps the process media inside the process chamber. Media classification is also available within the process/separation area. This eliminates the need for messy external separators and media return conveyors.

Features

- “U” Shaped Process Channel

- Full, u-shaped process channels ensure full media roll (no siding) and more turns of the part as it advances.

- Combo Available

- The Multi-Pass® is also available as a MPC (Combo) which offers the potential for a drying channel on the process bowl. This reduces the need for external systems requiring more floor space.

- Versatile

- The Multi-Pass® machine can also operate as a continuous process machine using part to media ratios used in conventional processes.

- Multiple Sizes Available

- Available in several sizes, allowing for part size, geometry, and the process cycle time needed.